Press release -

Thousands of tonnes of air pollution could be reduced by changing the way we dry our laundry

A new study has revealed that tumble drying a load of laundry releases almost the same amount of potentially harmful microfibres into the air as those released down the drain during machine washing of the same load.

Researchers from Northumbria University, worked in partnership with scientists at consumer goods giant Procter & Gamble on the study, which is published in the scientific journal PLOS ONE.

The team found that the use of fabric conditioners and dryer sheets, especially in combination, could significantly reduce microfibre release from tumble dryers.

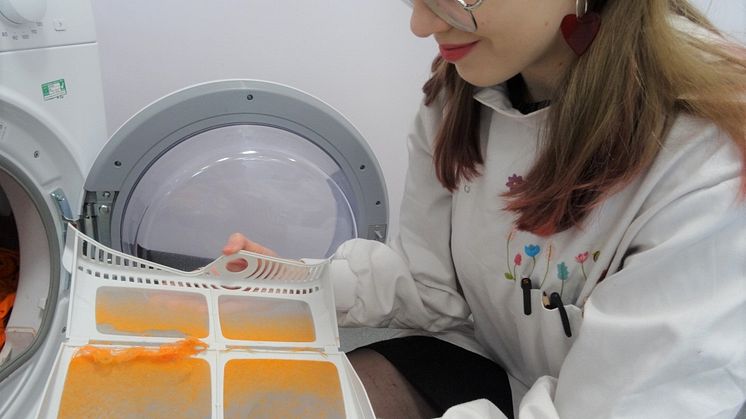

They also found that lint filters with smaller pores would trap larger masses, resulting in far fewer microfibres being released into the air, and that lint filters were better at capturing polyester fibres than cotton fibres. This means that most microfibers released into the air by dryers are likely to be cotton.

While extensive research has been carried out into the quantities of microfibres released down the drain by washing machines, far less is understood about the release from tumble dryers.

Recent analysis has found that washing laundry could release as much as a million tonnes of microfibres annually worldwide, posing potential risks to aquatic ecosystems.

However, when these miniscule fragments of clothing are released into the air during tumble drying with vented dryers, they not only pose a risk to the environment, but potentially also for human health.

Dr Kelly Sheridan, an expert in textile fibres at Northumbria University, worked alongside researchers at Procter & Gamble to measure the quantity of microfibres released during the washing and drying of clothing comprised of polyester and cotton. The research spanned both European and North American products and washing conditions and involved over 1,200 garments.

“By measuring microfibres released during the whole laundering process we found that microfibre loss through domestic drying is a huge concern,” she said.

“Ours is the first study that has simultaneously quantified microfibres released from clothing during washing alongside that released when the clothing is then tumble dried.

“We measured the volume of microfibres released during washing, as well as those captured in lint filters when tumble dried.

“Our study found that domestic dryers produce comparable quantities of microfibres that could be released to the air as we already see going into our water systems from a standard washing cycle.

“While many microfibres can be captured in lint filters during drying, if the pore size is too large, a significant amount will be released into the air, comparable to the amount released down the drain in washing.”

Dr Sheridan added: “It is critical to our understanding of the impact of microfibres on human health and the environment that all the potential pathways for microfibre release, including air, are assessed. Airborne fibres are just as concerning as those present in wastewater.”

Dr Neil Lant, a Research Fellow at P&G and their leading scientist on this study, added: “The recent rises in energy costs have led us all to think carefully about the financial impact of using dryers, but few are aware of their impact on particulate air pollution.

“These latest findings are a call to action for the appliance industry to improve the efficiency of fibre filtration systems in vented dryers and drive the conversion to condenser dryers with no airborne fibre release, especially super energy efficient heat pump dryers.

“While we know that people in different parts of the world and in different types of households may choose alternative ways to dry their clothing, our findings in this study relate to the impacts of vented tumble drying. Further research would be needed to assess the impacts of other drying methods.”

Procter & Gamble has been working with analytical and forensic fibre science experts at Northumbria University for over five years to improve our understanding of microfibre release during washing and drying.

Jerry Porter, Senior Vice President R&D, Global Fabric Care, Flavors and Fragrance and Fabric & Home Care Sector at P&G commented: “We are very pleased with the results from this latest study with Northumbria University, showing how products like liquid fabric softener or dryer sheets can reduce airborne fibre pollution from dryers. This and the other findings from the research will help us partner with the textile and appliance industries to identify long-term solutions to this complex problem.”

The complete findings of this study, The Impact of Fabric Conditioning Products and Lint Filter Pore Size on Airborne Microfiber Pollution Arising from Tumble Drying, by Northumbria University in collaboration with Procter & Gamble, are now published in PLOS ONE.

From modelling the impact of melting ice sheets on global sea level, to developing new technologies that will make homes and products more sustainable and efficient, Northumbria researchers are playing a leading role in helping us to live more sustainably in future.

Click here to find out more about some of the world-leading research Northumbria University is undertaking in all aspects of climate change

Topics

Categories

Northumbria is a research-intensive modern university with a global reputation for academic excellence. Find out more about us at www.northumbria.ac.uk --- Please contact our Media and Communications team at media.communications@northumbria.ac.uk with any media enquiries or interview requests ---