Press release -

Multidisciplinary partnership awarded ‘outstanding’ rating

Northumbria University is proud to announce that a Knowledge Transfer Partnership project, which has brought together industry and academic experts to develop a new biomedical device, has been given the highest possible rating by an independent government assessor.

Knowledge Transfer Partnerships (KTPs) are an Innovate UK programme, designed to encourage collaboration between academia and industry, facilitating the transfer of knowledge and technology to increase competitivity and to promote a culture of innovation within the industrial arena.

Two years ago Epigem, a micro-engineering company based in Redcar, established a KTP with Northumbria University, in Newcastle upon Tyne. The aim was to create a medical device to test for a range of diseases such as Bovine Tuberculosis and Johne’s disease (paratuberculosis) in cattle.

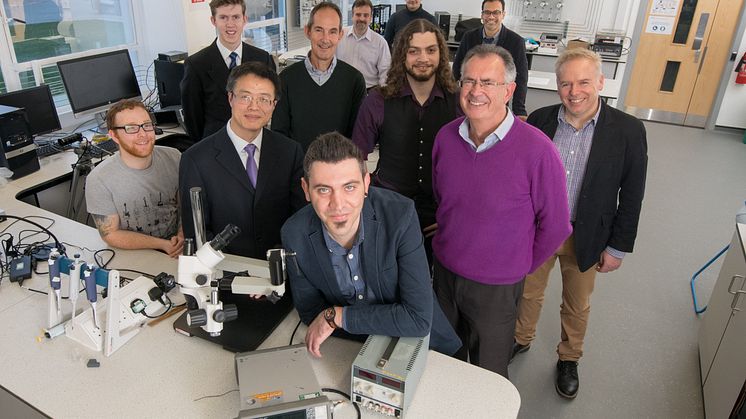

The project involved academics from across a variety of disciplinary areas, with experts in engineering, smart materials, control and electronics, physics and industrial design working with Epigem to develop a product prototype which is both effective and user-friendly.

The KTP has resulted in Epigem taking a whole new approach to product development through the incorporation of product design. Traditionally its core business has been manufacturing specialist parts which are then built into diagnostic devices made by other companies. Now, thanks to the KTP, Epigem will be able to reach new markets by designing and producing own-brand, consumer-ready products.

The partnership between Epigem and Northumbria has now been rated as 'outstanding' by Innovate UK, the UK's Innovation Agency. John Clayton, Knowledge Transfer Adviser at Innovate UK, was involved in the project from the start and provided insights and guidance to the partners throughout.

Speaking about the KTP’s success he said: “Projects that are awarded an Outstanding grade typically demonstrate an innovation-led approach to disrupt the market and embed a new process and culture in the business that facilitates further innovation.

“Bringing together Northumbria researchers from physics, engineering and design in the KTP helped Epigem not only develop a new product for the global health market but also new techniques to develop their business.”

Epigem specialises in producing bespoke microengineering for microfluidics devices and flexible electronics, with customers all over the globe. Discussing the KTP, Managing Director Dr Tim Ryan explained: “We have always produced the technical components for other people’s instrumentation, but this means we rarely hear feedback from the end users about the products, or how it could be effectively improved. That is why a few years ago, we made the decision to start developing Epigem own-brand products for the first time, with a real focus on customer experience.

“We knew working in partnership with a university would give us the academic expertise and innovation we needed. It was clear that Northumbria encouraged a multidisciplinary way of working, with academics from different faculties and departments able to work alongside each other and share their skills to create both the technology required for our device and the final product.

“The product we wanted to develop required expertise in micro-electronics, software engineering and smart materials, as well as industrial and product design, which was a completely new area for us. Northumbria University has academics working in all these fields and, more importantly, had the ability to bring them together to work on this project collaboratively.”

KTPs are three-way partnerships which see a graduate (known as an Associate) work with a business to lead a strategic project. Associates are supported by the company as well as the university, which provides academic advice and expertise as well as research facilities.

The benefit for the company is the creation of new products or service innovations, while the academics have the opportunity to further their research by applying it within an industrial setting. In addition, the academic team is exposed to a range of cutting-edge manufacturing processes and world class engineering facilities.

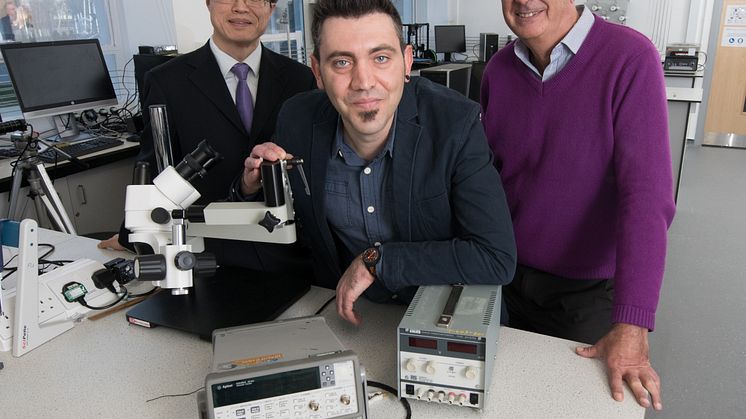

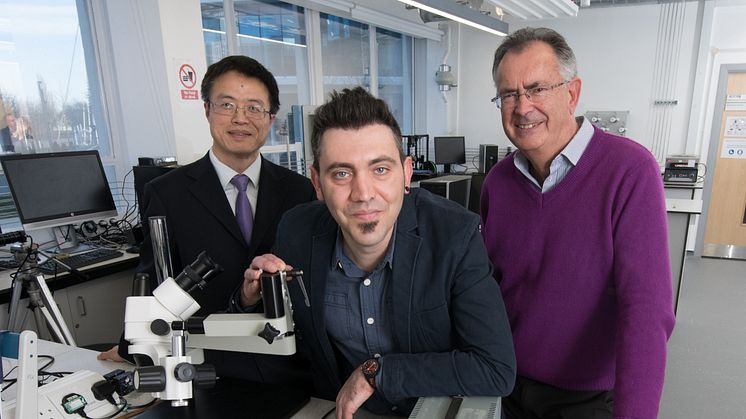

The Epigem KTP was led by Associate Dr Pep Canyelles Pericas, who was instrumental in bringing together the different academic experts required to meet the project’s objectives.

He said: “This was a really exciting project to be part of because it was holistic – not only were we designing the technology behind the product, we were actually looking at the product as a whole. We were constantly asking ourselves how the consumer might use this device and how we could reflect their requirements in our finished design.

“We are very lucky at Northumbria to have world-class experts in both smart materials and industrial design. Not only that but we have an ethos of collaboration and multidisciplinary working – bringing different skills together to create a product which not only performs well technically but is also intuitive for the end user.”

Northumbria’s expertise in smart materials was a key reason it was chosen as a KTP partner by Epigem. Professor Richard Fu, of Northumbria’sDepartment of Mathematics, Physics & Electrical Engineering, was the academic lead supervisor for the project. He has an international reputation for his research into smart thin film materials.

Speaking about the project, Professor Fu said: “Not only were we developing our research and designing the technology required, but also we were applying these technologies directly to a real product for the market. The technology itself is a platform, so it could in future be applied to detect other types of diseases, such as influenza, malaria and HIV.”

Incorporating design-led innovation into Epigem’s development process was a key aim of the KTP, and with an international reputation for innovation, Northumbria’s School of Design was ideally placed to provide the expertise required.

Industrial Design expert, Associate Professor Stuart English, whose research has resulted in the creation of new working methods, new products and new Intellectual Property for a wide variety of companies, led on the design element of the KTP.

He said: “In this project we took a design-led standpoint to explore how the science involved in the product was going to be used by real people in context and developed a business model that would make it a viable commercial proposition. We carried out a lot of research into the Intellectual Property landscape to understand the existing knowledge in this field and to identify our own contribution to the industry.”

As well as bringing together different academic staff, the project also involved a number of Northumbria University students on placement, providing them with valuable industry experience.

Speaking about the success of the project, Dr Pep Canyelles Pericas added: “This KTP project has resulted in a platform technology that can be applied to a variety of biomedical applications. In effect we have demonstrated the suitability of thin film surface acoustic wave devices in an industrial context. Epigem is using the findings to consolidate its position as a market pioneer with further industry-led innovation projects.”

The partnership between Northumbria University and Epigem received financial support from the Knowledge Transfer Partnerships (KTP) programme. KTPs aims to help businesses to improve their competitiveness and productivity through the better use of knowledge, technology and skills that reside within the UK knowledge base. This successful Knowledge Transfer Partnership project, funded by UK Research and Innovation through Innovate UK, is part of the government’s Industrial Strategy.

If your business is working on a project that would benefit from a new way of thinking, a Knowledge Transfer Partnership with Northumbria University could be the solution. Find out more by visiting www.northumbria.ac.uk/business-services/develop-your-business/knowledge-transfer-partnerships/

The full team working on the KTP project were:

Epigem:

- Dr Tim Ryan, Managing Director: chair of the Knowledge Transfer Partnership project management team

- Dr Simon Allen, Chief Scientist: oversaw the daily KTP development as company supervisor. His expertise in optical measurement systems and prototyping electronics played a key role in the project’s success.

- Phil Summersgill, Principal Engineer: provided key advice on microengineering processed and microfluidic integration. Phil has over 30 years of experience in engineering roles.

Northumbria University:

- Dr Pep Canyelles Pericas, KTP Associate: led the KTP and was instrumental in bringing together the different academic experts required to meet the project’s objectives.

- Professor Richard Fu, academic lead supervisor: has over 20 years of experience in lab-on-chip technology, advanced thin film materials, biomedical microdevices, micromechanics, micro-electromechanical systems, sensors and microfluidics, smart thin films, nanotechnology and system integration. Particularly interesting for this project was Richard’s pioneering work on thin film acoustofluidic devices, which are industrially scalable for mass production.

- Saqib Ali and Robert Allen, final year Design for Industry students: Both Saqib and Robert contributed to the KTP, exploring how the product would fit within the context that it would be use in. Saqib was instrumental in the design aspect, devoting his Industrial Design course placement to the KTP. Meanwhile Robert provided design thinking consultancy support. Saqib commented: “It was amazing working alongside professionals, learning core skills in communication, team work and project management. We had phenomenal supervisors, always encouraging, pushing us to do our best, teaching us important skills that will benefit us in years to come.” Robert added: “It was an absolute pleasure to be involved in the Epigem KTP. The work provided a fantastic opportunity for us as undergraduate students to share our design skills in a professional context.”

- Jethro Vernon, Northumbria Engineering graduate: Jethro spent last Summer working with Epigem at their base in Redcar, and is now pursuing his PhD at Northumbria with a scholarship. Jethro’s engineering skills helped the team to assemble a fully functional prototype for testing and demonstration at a high throughput screening lab.

- Dr Richard Binns, Head of Department of Maths, Physics and Electrical Engineering: provided valuable technical advice throughout the project.

- Krishna Busawon, Professor in Control Systems Engineering: played a significant role in the project bringing his expertise in electronic instrumentation, interfacing and control.

- Adam Cosheril, Senior Technician in Additive Manufacturing and Rapid Prototyping: on hand throughout the KTP to manage Northumbria’s state-of-the-art facilities. This included a variety of 3D printing technologies and laser cutters. Rapid prototyping was intensively employed to enclosure electronic boards and to create prototyping stands and cartridges. Saqib worked closely with Adam to identify the most suitable solution for each aspect of the project.

Topics

Categories

Northumbria is a research-rich, business-focused, professional university with a global reputation for academic excellence. To find out more about our courses go to www.northumbria.ac.uk

If you have a media enquiry please contact our Media and Communications team at media.communications@northumbria.ac.uk or call 0191 227 4604.